Motors and Reductors in Electric Vehicles

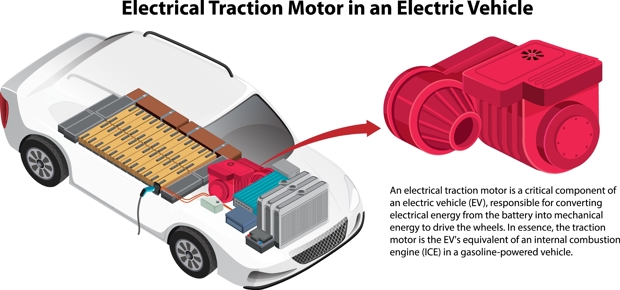

Electric motors used in EVs require very little maintenance over the years. With very few moving parts, electric motors are highly reliable and durable. However, when a problem is detected with the motor or its components, the bill can be very costly. Only repair shops specializing in electric vehicles are equipped to detect potential problems and carry out mechanical diagnostics on these motors.

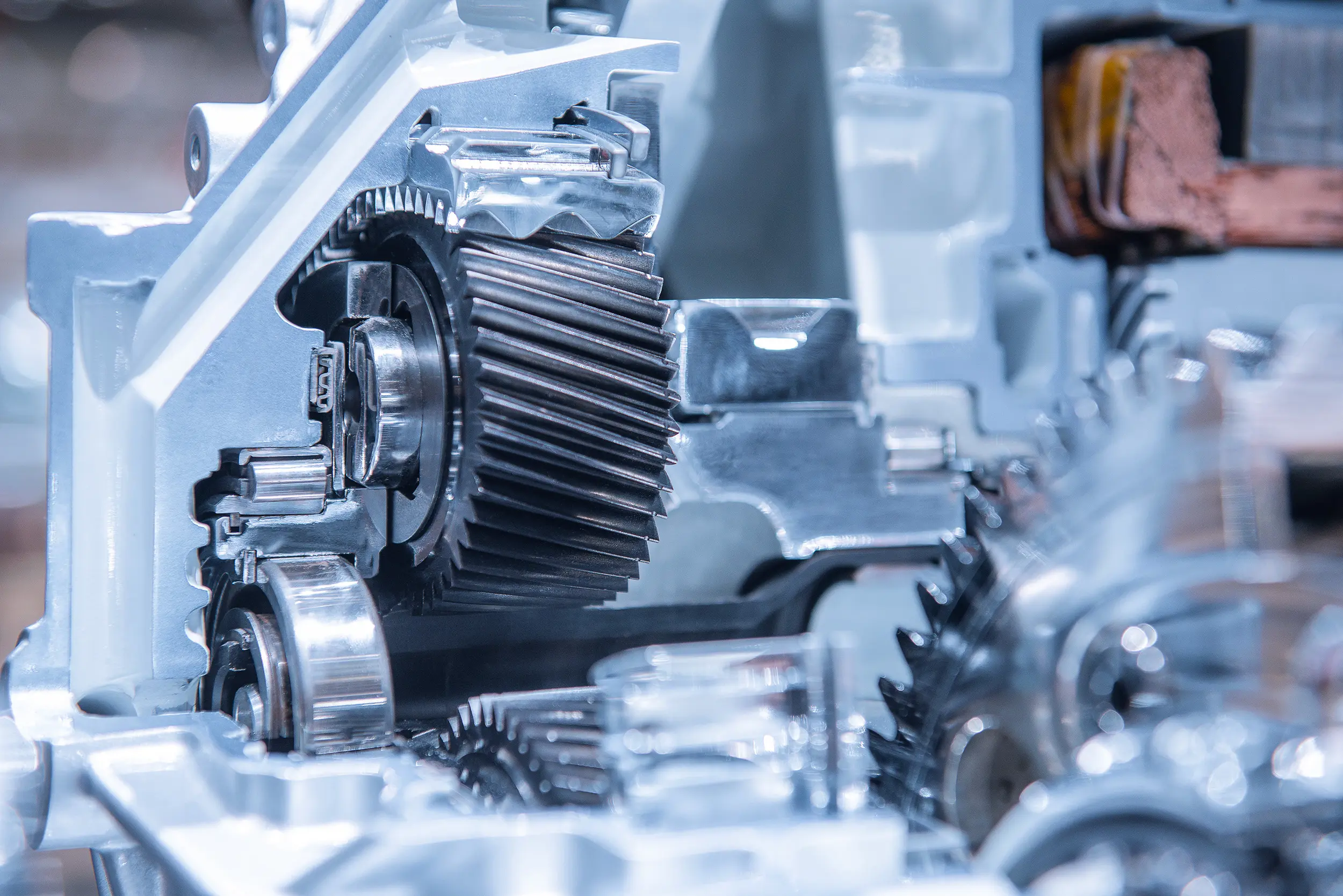

Electric vehicles have no transmission, which is a big advantage over internal combustion engines and their complex, multi-speed drives. But like all moving components, they need to be lubricated to prevent wear. The mechanical parts of an electric vehicle are lubricated with grease or liquid, and the same applies to reductors and differentials.

Periodic Maintenance is Essential

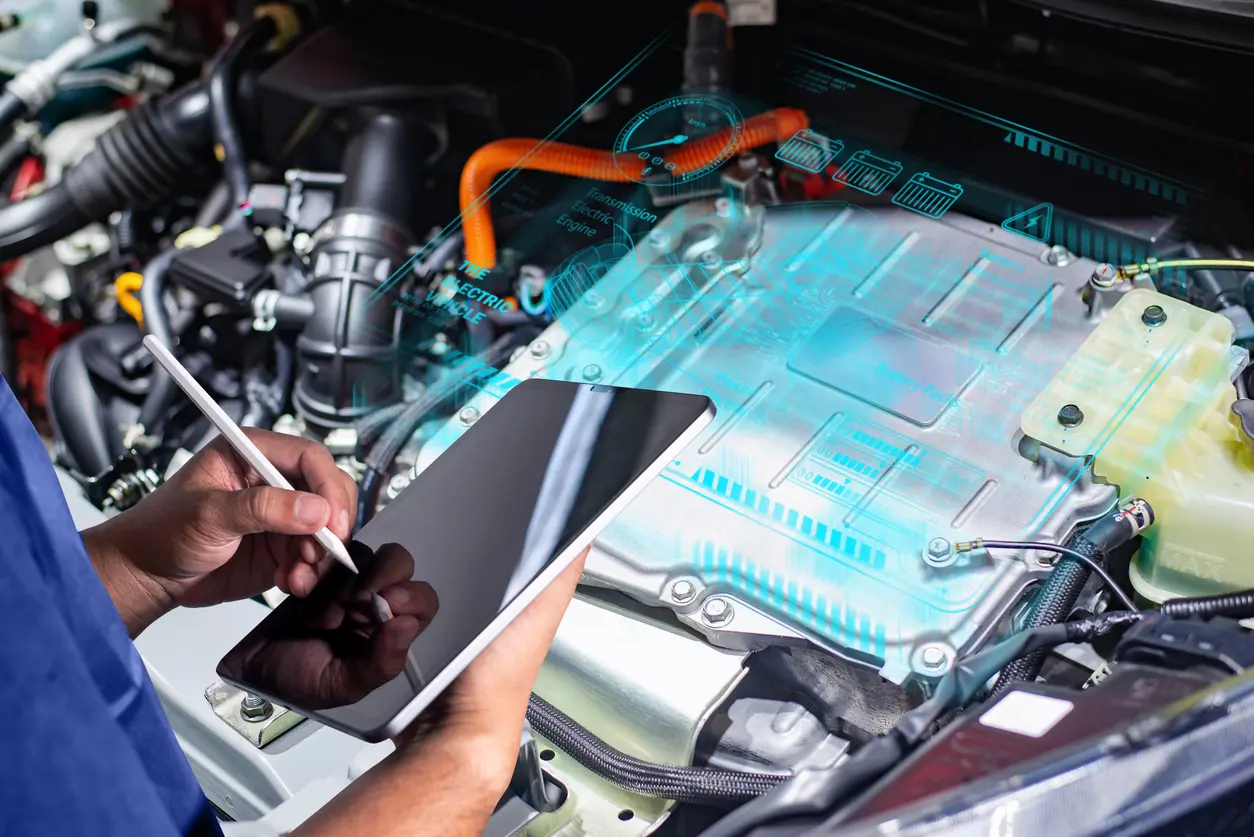

Proper periodic maintenance, in line with manufacturer recommendations, is essential and is the only way to detect small problems that can be easily resolved before they become too big.

The most frequent inspection and replacement of fluids concerns the reductor, but the interval is not comparable to that of internal combustion engine vehicles: it is often scheduled at around 100,000 km, whereas on average, an oil change on a combustion engine is required between 6,000 and 8,000 km.

Inspection and analysis are crucial to detect problems that can be solved before it’s too late.

NexDrive technicians are trained to check the specific components of your electric vehicle while respecting safety standards (certain high-voltage components can only be checked and maintained by qualified technicians). NexDrive has the most demanding certification program in Canada, and our technicians are already experts in traditional vehicle maintenance and repair. By trusting your local NexDrive service center, you’re making the best choice for you and your car.

Tips and Tricks

Why do electric car tires wear out so fast?

EV tires experience increased tread wear because of instant torque and unsprung weight. Learn why electric vehicles lead to worn-out tires and how to extend the lifespan of EV tires with proper maintenance.

Why regenerative braking is bad for your brake pads

Regenerative braking improves energy efficiency, but can cause brake pad issues because of reduced mechanical brake use. Learn how to maintain your brake system and prevent costly repairs in this article.

Does an EV need regular general maintenance?

Although EVs require less maintenance than gas-powered vehicles, they still need regular care. Learn about battery health, brake maintenance, and more here.