What is the Difference Between Electric and Conventional Vehicle Suspension and Steering Systems?

Suspension and steering systems on electric and internal combustion engine vehicles are almost identical. This means that the same maintenance and inspections are required for both types of vehicles.

However, there are some important suspension differences:

- Electric vehicle batteries are heavy, and the total weight of these vehicles is generally 25% higher than conventional vehicles.

- Electric vehicle batteries are often placed under the car or integrated into the chassis, lowering the center of gravity and improving handling.

- The high-torque motor and low center of gravity place greater demands on the suspension components of electric vehicles.

Regular Inspection of Suspension Components is Essential

Regular suspension component verifications help to identify any potential problems early on, avoiding more extensive damage and costly repairs later on. This is particularly important for electric vehicles, as suspension component malfunctions can harm overall vehicle performance and efficiency.

What’s more, a well-maintained suspension system helps to improve handling and stability, which in turn enhances safety on the road. Since electric vehicles require specialized maintenance due to their distinctive design and technology, it’s essential to pay particular attention to suspension components.

EV Steering Components Are Similar to Those of Conventional Vehicles

Your driving style and the environment in which you drive your vehicle will have a considerable impact on these components. As with conventional cars, salt, cold and humidity accelerate the wear of all rubber bushings, and can subsequently corrode electrical or internal components.

Steering components are often made up of electric steering racks, as on new-model conventional vehicles. Any damaged joints will allow moisture to penetrate the system and corrosion to spread. The cost of replacing a steering rack can run into thousands of dollars, so checking steering components is crucial.

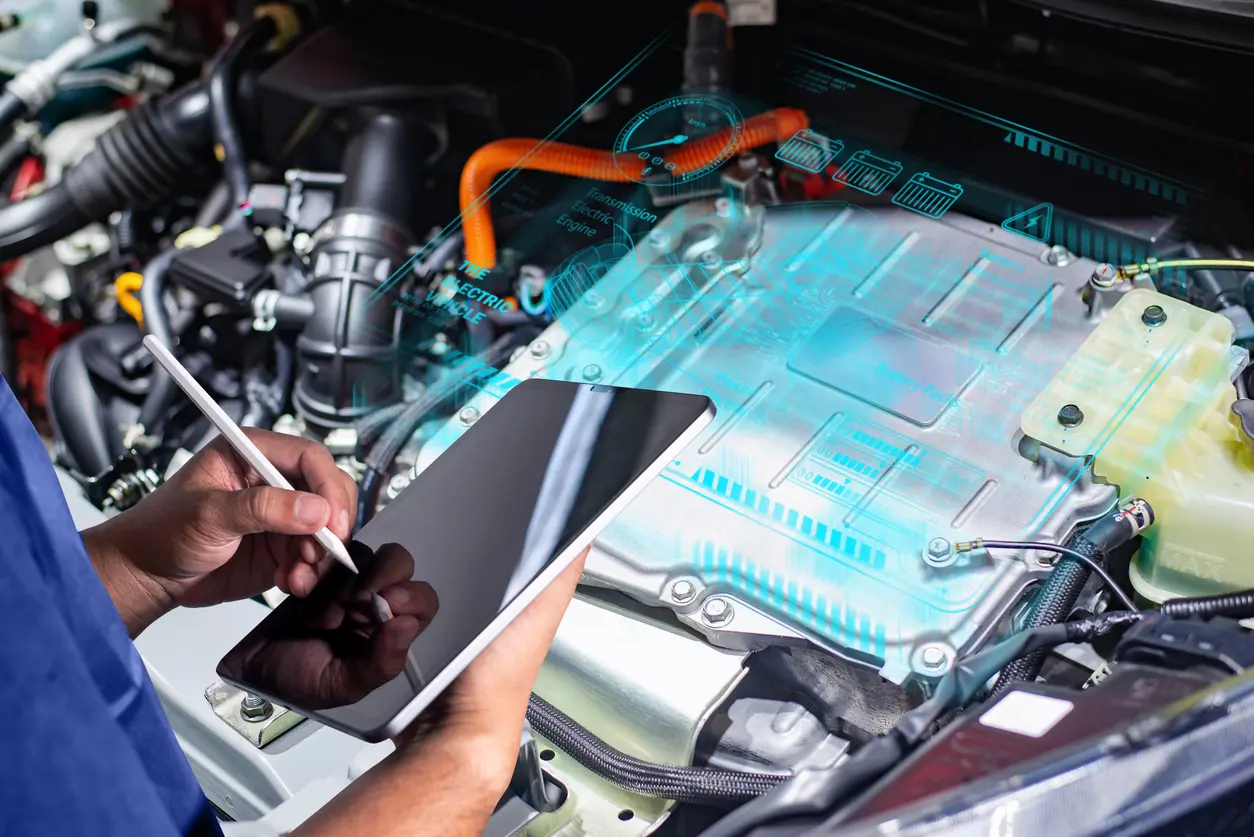

During the inspection, our NexDrive experts will check the wear of the main suspension and steering components and carry out a diagnosis of all safety components, including bushings, ball joints and other safety-related parts.

What Happens if Your Electric Vehicle Hits a Pothole?

As with conventional vehicles, small potholes shouldn’t be a problem for your electric vehicle. That said, if you feel that your vehicle is driving differently, it is important to have it inspected. If your car no longer complies with wheel alignment specifications, it could damage your tires and hurt your wallet.

In addition, there is a real risk of damage to the battery compartment after hitting a pothole. If you notice issues with the battery, or if you suspect the chassis hit something, it’s important to have your vehicle inspected. Likewise, any strange noise during acceleration or when turning corners should lead to an inspection.

Finally, the heavy weight means that your suspension components may be out of spec, which means that alignment is necessary and the rest of your vehicle should be inspected.

NexDrive technicians are trained to check the specific components of your electric vehicle while respecting safety standards (certain high-voltage components can only be checked and maintained by qualified technicians). NexDrive has the most demanding certification program in Canada, and our technicians are already experts in traditional vehicle maintenance and repair. By trusting your local NexDrive service center, you’re making the best choice for you and your car.

Tips and Tricks

Why do electric car tires wear out so fast?

EV tires experience increased tread wear because of instant torque and unsprung weight. Learn why electric vehicles lead to worn-out tires and how to extend the lifespan of EV tires with proper maintenance.

Why regenerative braking is bad for your brake pads

Regenerative braking improves energy efficiency, but can cause brake pad issues because of reduced mechanical brake use. Learn how to maintain your brake system and prevent costly repairs in this article.

Does an EV need regular general maintenance?

Although EVs require less maintenance than gas-powered vehicles, they still need regular care. Learn about battery health, brake maintenance, and more here.